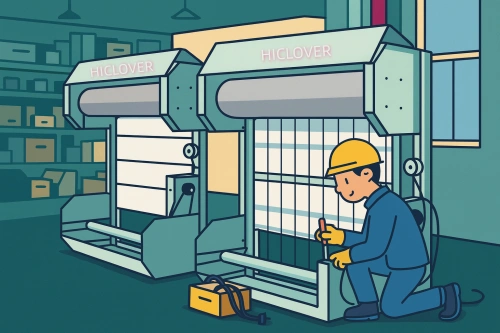

HICLOVER Automatic Roll Air Filter Solutions for Australian Mining Ventilation Systems

Australia’s mining industry operates in some of the harshest and dust-laden environments on earth. From copper mines in Western Australia to underground operations in Queensland, air quality control is critical to worker safety and equipment longevity. The HICLOVER Automatic Roll Air Filter offers a modern solution for dust suppression in Australian copper mines, providing a PLC-controlled, self-winding filtration system that minimizes manual maintenance while ensuring consistent airflow in mining and heavy industrial environments.

Automatic Roll Air Filter for Dust Suppression in Copper Mines

In open-pit and processing areas of Australian copper mines, dust from ore handling and crushing reduces air visibility and damages machinery. HICLOVER’s automatic roll air filter for dust suppression in Australian copper mines integrates a motorized media roll with differential pressure monitoring. The filter automatically advances fresh media when dust loading increases, maintaining stable resistance and reducing downtime.

This adaptive system is especially valuable in high-temperature and high-particulate conditions typical of the Pilbara and Mount Isa regions. With heavy-duty steel housing and auto-reset PLC logic, it outperforms traditional panel filters and cartridge systems in both durability and automation.

Learn more at www.cloverfilter.com.

Prefilter for Underground Mine Refuge Chamber Ventilation

In underground refuge chambers, clean and breathable air is a life-critical requirement. The prefilter for underground mine refuge chamber ventilation in Australia must remove coarse dust before the secondary HEPA or carbon stage. HICLOVER’s automatic system serves as this prefiltration stage, featuring:

-

Programmable PLC motor drive for continuous filter advancement.

-

Low-resistance synthetic media suitable for high humidity.

-

Auto-limit protection preventing over-winding or paper jams.

By reducing filter replacement frequency and manual inspection, this system improves reliability and aligns with Australian Mine Safety Standards (AS/NZS 2290). Visit www.cloverfilter.com for technical documents and specifications.

Automatic Winding Filter Unit for Heavy Industry Corridors

Australian heavy industry corridors―spanning smelting, rail maintenance, and mineral export terminals―require large-volume ventilation systems that stay online 24 hours a day. The automatic winding filter unit for Australian heavy industry corridors uses dual-shaft synchronized motors, pressure sensors, and a touch-screen control interface. It supports horizontal or vertical installation within HVAC ducts or direct process air intakes.

Key features include:

-

Smart differential pressure control for automatic roll change.

-

Modular stainless-steel frame design to suit various duct sizes.

-

Continuous filtration without system shutdown, essential for conveyor tunnels and dust-extraction halls.

Why HICLOVER Technology Leads

HICLOVER’s design emphasizes reliability, automation, and low operator intervention. Each unit is engineered for:

-

Reduced life-cycle cost through automatic media utilization.

-

Integration with PLC/SCADA systems for real-time status feedback.

-

Compliance with ISO 16890 and EN 779 efficiency standards.

These filters serve not only mining but also marine, steel, and energy sectors―industries requiring continuous, high-airflow dust control with minimal human access.

Technical Highlights

-

Power supply: 220 V/50 Hz single phase or 380 V three phase.

-

Motor rating: 100 W C 200 W, geared for constant-torque drive.

-

Control mode: PLC automatic with manual override switch.

-

Filter media: G3CG4 class non-woven synthetic fabric.

-

Frame material: Galvanized or stainless-steel housing, optional epoxy coating.

-

Max airflow: Up to 15 000 m3/h per module.

Applications Across Australia

-

Copper and nickel processing plants.

-

Underground ventilation and refuge air intake systems.

-

Ore handling tunnels and conveyor corridors.

-

HVAC intakes for remote mining camps.

Each deployment can be configured for local environmental conditions such as high dust load, coastal humidity, or temperature extremes from the Kimberley to South Australia.

Conclusion

The HICLOVER Automatic Roll Air Filter represents a new generation of intelligent prefiltration technology tailored for Australia’s mining and heavy industry environments. By combining PLC automation, continuous operation, and rugged construction, it provides a long-term air quality solution where manual maintenance is difficult or hazardous.

Contact:

Mobile (WhatsApp): +86-13813931455

Website: www.cloverfilter.com

Email: cloverfilter@gmail.com

2025-10-09/20:10:19